Notching Saw Features:

- Notching Saw is developed and designed by adopting mature Italian design idea in combination with the newest application requirement and habit

- The machine is mainly used for the processing of end surface connector of aluminum curtain wall profile, window and door profile and other aluminum industrial profiles.

- It’s equipped with accurate digital display angle measuring device and high quality motor, as well as 22″ hard alloy saw blade, it has features of high linear velocity and precision and the swing angle of both blades is ±45°.

- It’s the most stable machine after release to market, and wins high appraisal and recognition of customers; it’s one of our featured machines.

Notching Saw Technical Parameters:

| No. | Parameter | NS-600 | NS-550 |

|---|---|---|---|

| 1 | Cutting Angle Adjustable | Fixed Cutting Angle | |

| 2 | Voltage | 380V 50Hz | 380V 50Hz |

| 3 | Power | 2*2.2Kw | 2*2.2Kw |

| 4 | Cutting Size | 205mm | |

| 5 | Motor Speed | 2850rpm | 2800rpm |

| 6 | Saw blade size | 600x30x128T | 450x30mm |

| 7 | Angle of Saw blade | +/-45° | fixed |

| 8 | Feeding speed of Saw | 0-3m/min | 0-3m/min |

| 9 | Angle of Working table | +/-45° | fixed |

| 10 | Dimension | 2350x1575x1800mm | 1600x1100x1500mm |

Notching Saw Advantage:

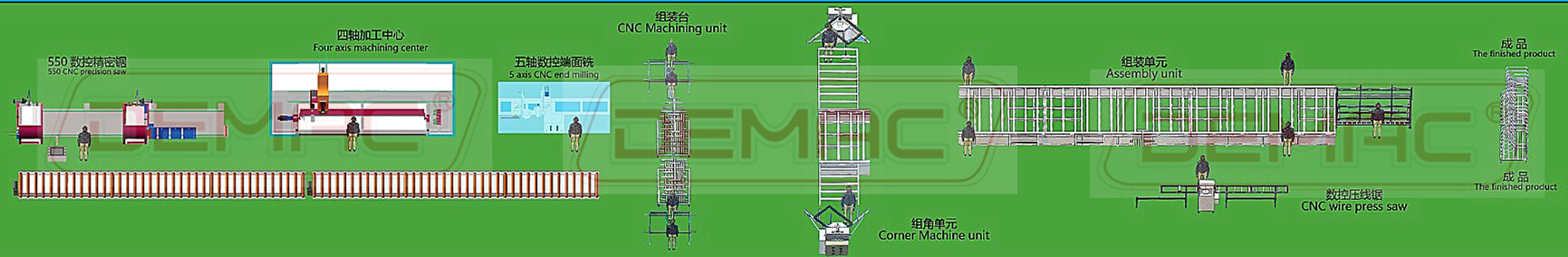

Aluminium Curtain Wall Unitize Notching Saw Machine is a great machine for unitized curtain walls. The machine is developed and designed by adopting experienced curtain wall processing. It combined with the newest application requirement and habit. The machine is mainly used for the processing of end surface joint of aluminum curtain wall profile, window and door profile and other aluminum industrial profiles. It’s equipped with accurate digital display angle measuring device and high quality motor, as well as dia.600mm hard alloy saw blade. It has features of high linear velocity and precision and the swing angle of both blades is ±45°. It’s the most stable machine after release to market, and wins high appraisal and recognition of customers.The Notching Saw Machine is a highly-efficient tool for cutting aluminium profiles. Its high-quality carbide saw blade and swinging arm feeding model offer superior performance and ease of operation. This machine can cut large-section profiles. Two saw heads allow it to cut at two different angles at the same time, allowing for higher processing accuracy. This unit also has vertical pneumatic clamping.The unitized curtain wall manufacturing process is divided into two major parts: fabrication and assembly. During fabrication, components are processed to meet specific requirements. Some components, like aluminum extrusions, need to be cut, grooved, notched, or drilled. To ensure accuracy and speed, automated notching saw machines are needed.

Reviews

There are no reviews yet.