Insulated Glass Unit Machinery

Insulated Glass Unit Machinery produces insulating glass. The common Double Glazing Equipment are including Insulating Glass Processing Line, and Auxiliary Equipments, which is for cutting and bending Aluminum Spacer, filling Desiccant, Butyl Coating, and second time Sealing. The Manual type machines are for small output quantities or special processing demands customers. Such as IGU Assembly Table, Glass Cutting Breaking Table, Economic machines, and Manual tools.

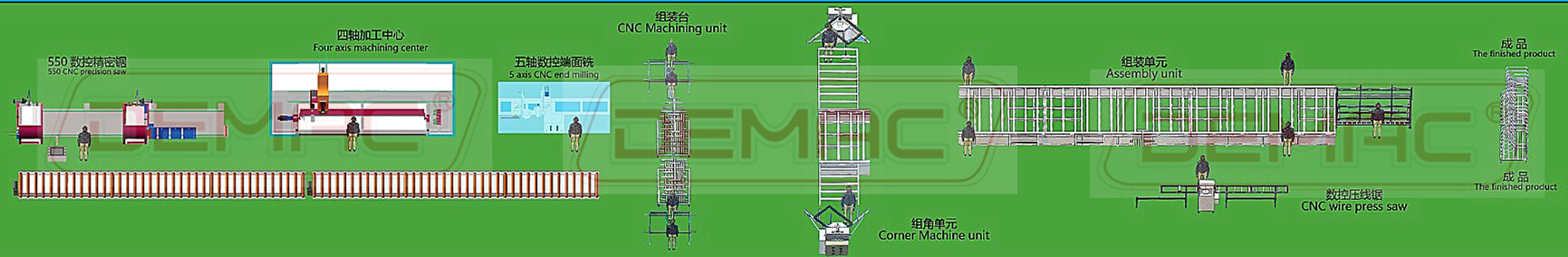

Automatic Double Glazing Equipment Processing Line is the main selling machine. It makes processing IGU Standardized production. Large output; Large plant area; Simple and convenient operation; Saving labor costs.

Manual Double Glazing Equipment: Suitable for small output, also can process special IGU. These equipment and tools can also be used as a complement to the automatic line.

Tell me your production demands. We will send the exact quotation for Double Glazing Equipment to you.

Nowadays the constructions and high rising building is becoming more and more energy saving. So it gives more requests on the glass technology application. We can see more changes on the Insulating Glass Unit. So the Insulated Glass Unit Machinery is designed with the latest technology and is capable of executing the complete process of Insulating Glass Manufacture. Double Glazing Equipment has all the necessary functions of inner and out-panel assembly, including stepped and same-edge glass processing. This Double Glazing Equipment is also capable of processing triple-layered and quadruple-layered beside the double glass.

The soundproofing properties of this type of window are also highly variable. The type of glass and interlayer can affect the amount of noise that enters the room. For example, asymmetric double/triple-glazed windows may be able to reduce noise, but they do not completely prevent it. If soundproofing is important for the building, you may want to use a thermal barrier air spacer in the windows. This will improve acoustics and reduce the transmission of exterior noise sources. In addition to reducing the amount of noise entering the building, double /triple-glazed windows reduce the amount of moisture that collects on window panes.

The airtight seal between the glass and the frame prevents condensation from the building, which can lead to mould growth. Moreover, thanks to the Insulated Glass Unit Machinery, the double/triple-glazed doors and windows are more energy efficient than single-glazed doors. You can also choose low-e glass or laminated glass for the windows to improve energy efficiency and control noise.

There are many factors to consider when choosing Double Glazing Equipment. A well-oiled processing machine can produce more glass than a manual line, and different glass manufacturers may require different types of equipment. If you're a new glass manufacturer, a Insulated Glass Unit Machinery Line may be the right choice. So the complete Double Glazing Equipment Production Line is composed by different sections, such as the Double Glazing glass washing Equipment, Conveyor Tables, Panel Pressing Machine, Insulated Glass Sealing Machine, Butyl Sealant Coating Machine, Glass Film Lamination Machine, automatic Aluminum Spacer Automatic Bending Machine and Desiccant Automatic Filling Machine ect.. so the Insulated Glass Unit Machinery Lines included above single unit machines. According to the glass size, there is several sized production line to meet different size processing request.

The business segment that you serve will dictate many of the requirements you have for your Double Glazing Equipment Production Line. You should know how much you anticipate sales of any-sized glass to be, and how much you will need to increase capacity. You can also decide whether to invest in a second the Insulated Glass Unit Machinery or reconfigure your existing Double Glazing Equipment. Both of these options are viable, and you should make sure to plan for growth. This will help you tap into a niche that you don't currently serve.

As more people demand energy-efficient buildings, the demand for insulating glass is predicted to continue to rise. While you may have a small or medium-sized production line, investing in insulated glass will allow you to stand out from your competitors. It will also give you an edge in the marketing game against your competition. And don't overlook the economic benefits of investing in an Insulated Glass Unit Machinery production line. Just remember to consider the costs and potential benefits before you decide to go ahead and purchase one.

1. Use Glass Edger to smooth the cut glass

2. Put the polished glass into the feeding section of the Double Glazing Equipment production line, and the glass will reach the installation section of Double Glazing Equipment production line after being washed and dried.

3. At the same time, use the Aluminum Spacer Bending Machine to bend the aluminum spacer into the required shape and size, then use the Desiccant Filling Machine to fill the molecular sieve desiccant into the aluminum spacer frame, and then use the Butyl Extruder Machine to apply butyl glue to both sides of the aluminum frame, and finally hang the aluminum frame on the Aluminum Spacer Frame Transfer Machine

4. Install the aluminum spacer frame on the first piece of glass that has been cleaned, and then it enters the plate pressing section of Double Glazing Equipment production line. After the second glass is cleaned, it also enters the plate pressing section of Insulated Glass Unit Machinery. After the plate pressing is completed, the Insulated Glass Unit enters the discharge section of Double Glazing Equipment production line

5. If the Insulated Glass Unit Machinery Line connected to an CNC Insulated Glass Unit Sealing Robot, it will automatically apply Two-component Silicone or Hot Melt Glue.

6. If Double Glazing Sealing Robot Machine is not connected, use a Vacuum Lifter or Glass Unloader to remove the Insulating Glass Unit. Then use Two-component Silicone Extruder, Hot Melt Machine or Insulated Glass Unit Sealing Machine for secondary sealing

7. Use Gas Filling Machine to fill the insulating glass with inert gas, such as Argon.

8. Finally, can use Film Lamination Machine to apply protective film on the surface of the Insulated Glass Unit to prevent scratches or dust.