Aluminum Window Crimping Machine

-

Single Head Corner Crimping Machine: This kind of corner joint machine is the most popular in the market. The occupy size is very small and very easy to operate. The Max. processing height is 160mm. The positioning plate, fixed model or up/down model according to your demands. The position of each crimping tools is adjustable.

-

Four Head Corner Crimping Machine: NC servo system control Vertical type machine, the Max. processing height is 120mm. Horizontal type machine is more advantage model with 17 axis. The position of each head can ajust according to production list automatically.

The Corner Crimping of Aluminum doors and windows is to use the corner connector to connect the cut profiles to form a frame. Because of the special installation position of the window, the window frame must be resistant to impact, wind pressure and temperature changes.

There are two common ways to make Corner Joint:

1. Use the screw set corners. This method does not need to buy Aluminum Window Crimping Machine, and the processing cost is low. The disadvantage is that during long-term use, there may be looseness and cracks in the gaps, which affect the sealing and safety of the window.

2. Use Aluminium Corner Joint Machine for Crimping Corner. Put the Corner Connector into the corresponding chamber of Aluminum Profile, and then squeeze the Corner Key and the Aluminum Profile together with Aluminum Window Crimping Machine. The frame assembled in this way has a flat surface, tight gaps, good compression and wind resistance, and long service life of doors and windows.

In addition, there are also customers who use movable Corner Connector and combined Corner Key for processing.

1. The most widely used one is the Single Head Aluminum Window Crimping Machine. It has two sub-categories: A. ordinary Single Head Aluminum Window Crimping Machine: processing ordinary door and window Aluminum profiles. B. Heavy-duty Single Head Aluminium Corner Joint Machine: the crimping pressure increases, the positioning plate moves up and down, and the processing range is enlarged. Heavy-duty Single Head Aluminium Corner Joint Machine is used to process large profile such as thermal break aluminum.

2. If the doors and windows are single in size but large in quantity, the Vertical Four Head Aluminum Window Crimping Machine is a good choice. It completes the Corner Crimping of the four corners at the same time, which is highly efficient.

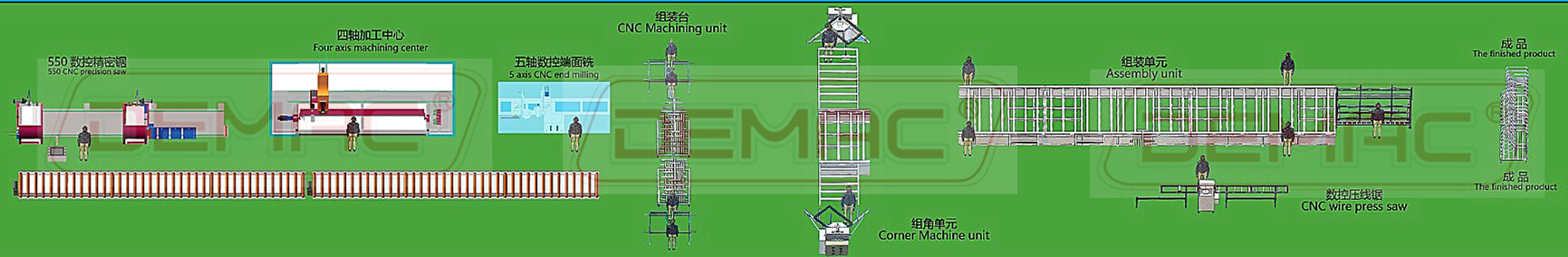

3. If you want to build a modern factory, the CNC 17-axis Horizontal Four Head Aluminium Corner Joint Machine is essential. The CNC Aluminium Corner Joint Machine is controlled by 17-axis servo system without manual adjustment of the machine heads position. Can be used in connection with production lines.