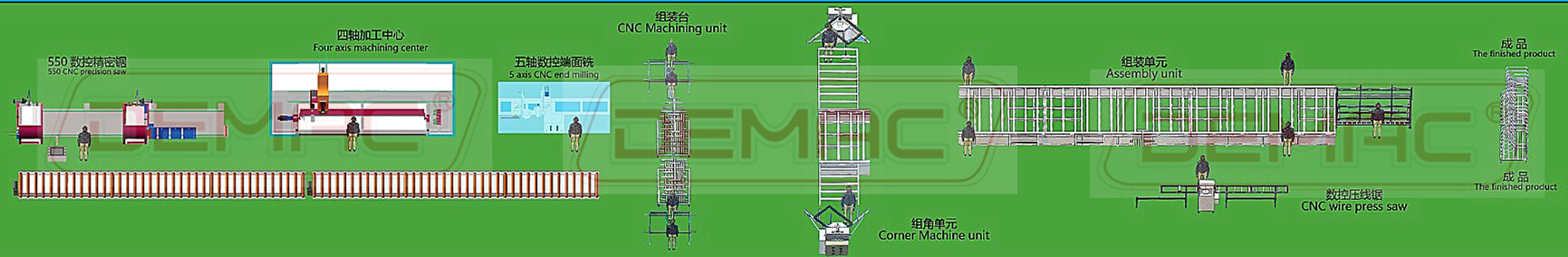

ACP Grooving Cutting Machine Features:

The Aluminium Composite Panel Grooving Machine is used for grooving lines on the aluminium composite panel. The vertical structure gives easy operation and convenient processing check. The machine is composed by the steel frame body, grooving head and the industrial dust collector. The grooving head can be rotary straight way for vertical and horizontal grooving. This grooving machine is well-known for its precision, durability, ease of use, and safety. With our developed grooving blades, the machine is available in various panel sizes, the model LMX-1600 is perfect for a wide range of applications.The grooving head is equipped with a groove blade holder that allows the operator to cut a strip of material from an aluminum composite panel. The strip can be up to 5mm thick and bend or fold. The machine has an adjustable blade grooving depth by the tool holder. The interval subsection orientation device and the lock device are set in the movable frame. There is pulling device at the bottom and middle position which is convenient for the different size processing;

The Electric Aluminium Composite Panel Cutting And Grooving Machine processing accuracy:

*. Groove linear in horizontal milling: ≤0.25/1000mm;*. Groove linear in vertical milling: ≤0.25/1000mm;*. Cutting surface roughness:Ra12.5∪m*. Two IS vertical slots max deviation from standard line ≤1;*. The parallelism of two milling slots in the same direction ≤0.25/1000mm

Aluminum Composite Panel Grooving Machine Technical Parameters:

| 1 | Voltage | 380V 50Hz |

|---|---|---|

| 2 | Power | 2.2Kw |

| 3 | Motor Speed | 2850rpm |

| 4 | Process Width | Max.4100mm |

| 5 | Process Height | Max.1600mm |

| 6 | Milling Cutter Size | 250x16x30mm, 92°& 135° |

| 7 | Cutter Size | 250x30x3.2mm |

| 8 | Dimension | 5400x1200x2600mm |

| 9 | Weight | 900kg |

Reviews

There are no reviews yet.